- Backer Springfield

- / Products

- / Commercial

- / Tubular heating elements for liquid

Tubular heating elements for liquids

Backer Springfield tubular heating elements represent a proven and safe technical solution for liquid heating. The Backer tubular heating element is the most frequent alternative when it comes to exact heating of fluids.

Tubular heating elements perform exceptional heat transfer by conduction, convection, or radiation to heat liquids, gases, air, and surfaces. Tubular elements have the unique ability to be designed and custom crafted to meet the specific requirements of any application, while exhibiting outstanding performance in the areas of heat transfer.

Backer Springfield offers a wide range of sheath diameters, end treatments, sheath materials and a large range of voltages, powers, lengths and shapes to ensure a cost effective and reliable design. We offer bend formations in most any shape, just submit your design folders and drawings for engineering review in order to provide the most efficient design for your application.

Backer Springfield manufactures tubular heaters that can be in contact with liquids for use in many different applications and Industries within the commercial segment, such as:

- Home & Comfort (clothes dryers, incinerating toilets, boilers, dishwashers, washing machines, small appliances, spas & hot tubs, steam generators, swimming pools),

- Foodservice Equipment (coffee machines, dishwashers, fryers, water heaters),

- Refrigeration (industrial refrigeration, ice makers),

- Scientific & Medical (hydrotherapy baths, water distillers, fluid analyzers)

- Transportation (fuel & fluid warming),

- Manufacturing and Processing (oil & gas processing, petrochemical processing), among others.

Backer Springfield’s engineering staff possesses technical expertise, R&D capabilities, and the ability to work closely with our customers allowing us to meet virtually every design challenge that has been presented and to produce the most reliable and effective heater for your application.

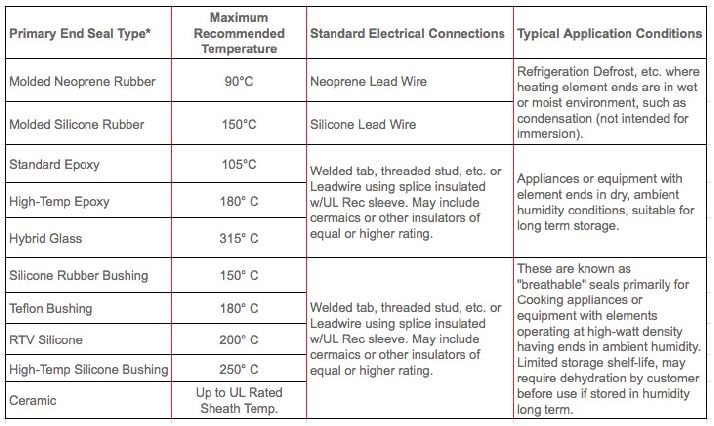

Backer offers multiple end seal treatments. The operating temperature of the heaters, as well as the storage, operation, and end user application will determine the appropriate seal material.

Depending upon the intended use, Backer utilizes our engineering capabilities to construct a heater based on your application specifications. Moisture resistant, water resistant, and waterproof elements can be made to fit your requirements.

Backer-Springfield is a manufacturer of high-quality heating products and, as such, we are only setup to sell to resellers and O.E.M. manufacturers. We are unable to fulfill requests direct from consumers. If you are a consumer seeking a replacement element for your appliance, please contact the manufacturer of your appliance or your local professional service technician for information on the required heating element(s).

Technical data

DESIGN OPTIONS

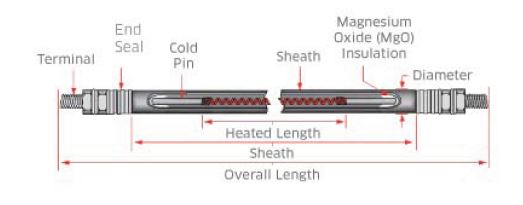

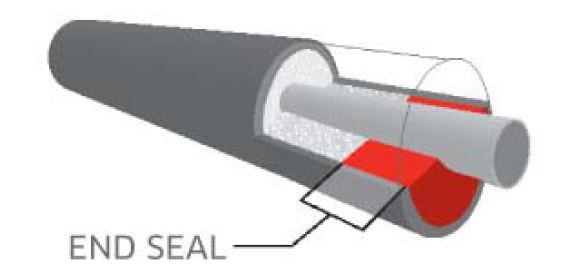

A tubular element has four basic components: a metal sheath, a helically wound coil of special resistive alloy, end seals, cold pins on each side of the coil, and magnesium oxide (MgO) insulating material. The tube is the outer casing of the heater and houses the other basic components. The cold pins protrude from the ends of the assembly to allow for

power connections.

END SEAL TREATMENTS

Backer Springfield offers multiple end seal treatments. The operating temperature of the heaters, as well as the storage, operation, and end user application will determine the appropriate seal material.

LEAD WIRES AND TERMINATIONS

The power connections to the heater assembly can be provided by either splicing lead wires to or directly welding terminals on the cold pins. Multiple lead wire types and terminal pin options are available.

Sheath Materials | Max Temperature |

Copper | 350°F/177C |

Aluminum | 500°F/260C |

Cold Rolled Steel | 750°F/399C |

.304 Stainless | 1400°F/760C |

.316 Stainless | 1400°F/760C |

.321 Stainless | 1400°F/760C |

Inconel 600 | 1800°F/982C |

Incoloy 800 | 1700°F/927C |

Incoloy 840 | 1700°F/927C |

.

Terminals | -Plated |

Stud Threaded Terminals | -6-32 |

Wall Thickness | -.018”-.049” |

Voltages | Up to 600 volts AC |

Cold Pins | -SS or Ni-Ply |

Sheath Diameter | -.250 -.430 |

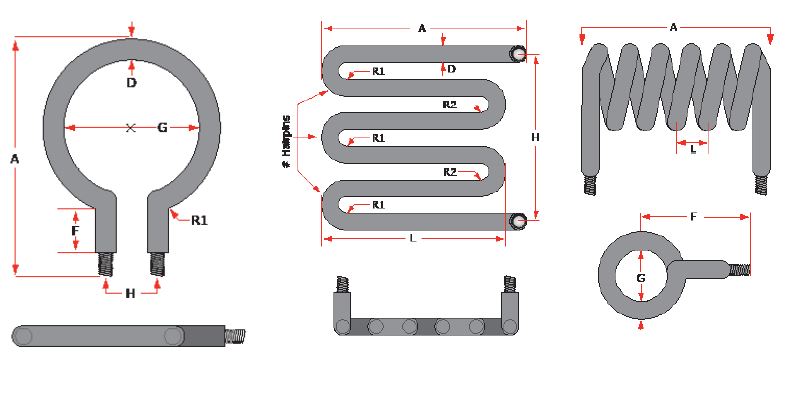

Bend Formations

Backer Springfield offers bend formations in most any shape, just submit your design folders and drawings for engineering review in order to provide the most efficient design for your application.

END SEAL CONSTRUCTIONS

END SEAL TREATMENTS

Depending upon the intended use, Backer Springfield utilizes our engineering capabilites to construct a heater based on your application specifications. Moisture resistant, water resistant, and waterproof elements can be made to fit your requirements. Alternately, elements may be supplied that make the customer responsible for properly sealing the ends after additional processing.

Example applications

- Water Heater

- Oil Heating

- Steamer

BACKER EHP INC. · 4700 JOHN BRAGG HWY · MURFREESBORO, TN 37127 · TEL: +1 (615) 907-6900 · [email protected]